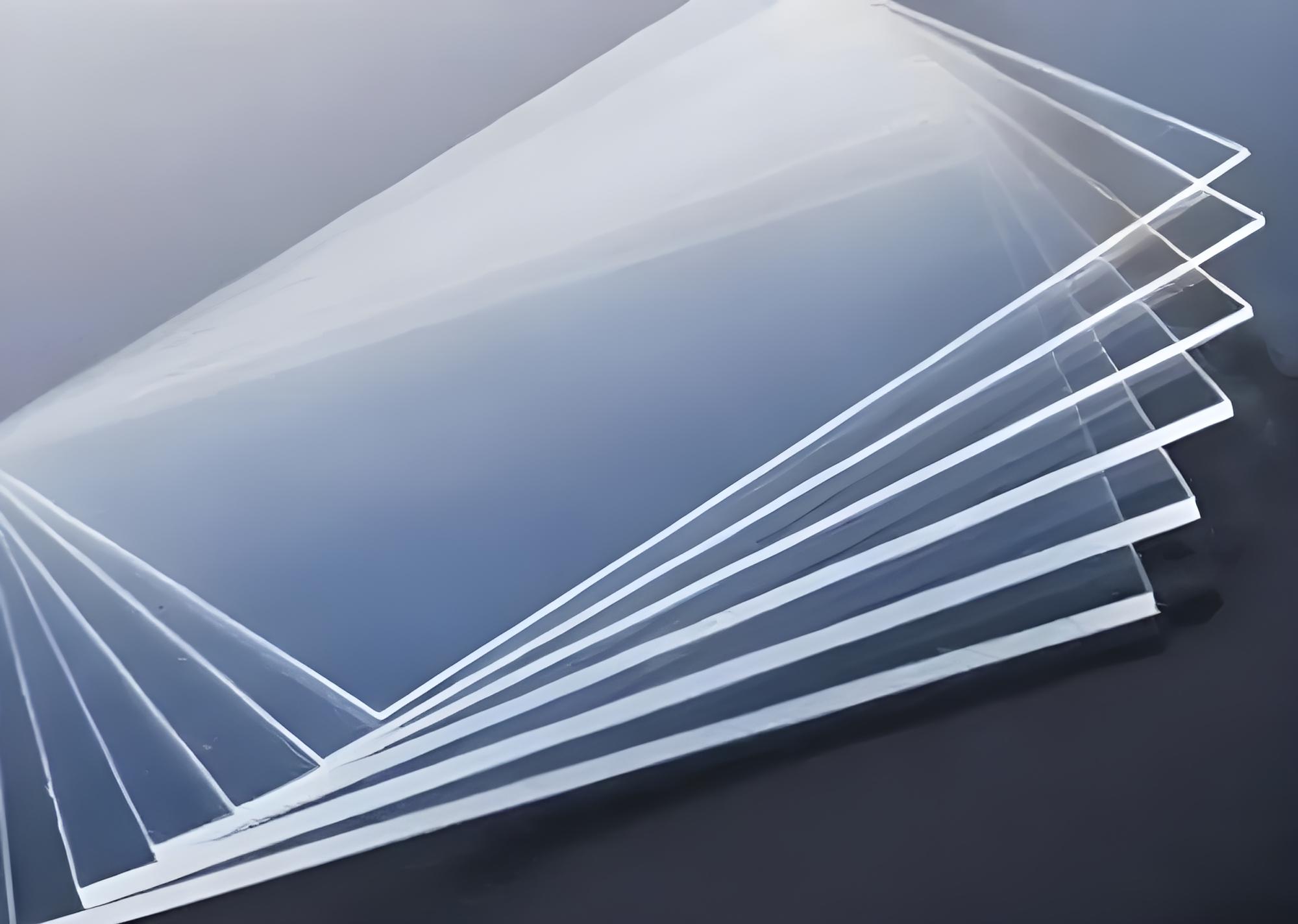

Igama lekhemikhali ye-acrylic yi-polymethylmethacrylate (PMMA ngesiNgesi). Ngenxa yeentsilelo ze-PMMA ezifana nobulukhuni obuphantsi komhlaba, ukuxutywa lula, ukuchasana kwempembelelo ephantsi, kunye nokusebenza kakubi kokuhamba kokubumba, ukuguqulwa kwe-PMMA kuye kwavela enye emva kwenye. Njenge-copolymerization ye-methyl methacrylate kunye ne-styrene kunye ne-butadiene, ukudibanisa kwe-PMMA kunye ne-PC, njl.

Indlela yokuziphatha yePMMAimbi ngakumbi kune-PS kunye ne-ABS, kwaye i-viscosity yokunyibilika ivakalelwa ngakumbi kutshintsho lobushushu. Ngexesha lenkqubo yokubumba, i-viscosity yokunyibilika iguqulwa ikakhulu ngokusekelwe kwiqondo lokushisa lokutofa. I-PMMA yipolymer e-amorphous enobushushu obunyibilikayo obungaphezulu kwe-160°C kunye neqondo lokushisa lokubola kwe-270°C.

1. Ukulahlwa kweeplastiki

I-PMMA inomlinganiselo othile wokungena kwamanzi, kunye nesantya sokufunxa amanzi kwi-0.3-0.4%. Isitofu sokubumba sifuna ukufuma ngaphantsi kwe-0.1%, ngokuqhelekileyo i-0.04%. Ubukho bobumanzi bubangela amaqamza, imimoya yomoya, kunye nokuncipha kokungafihli kwinyibilika. Ngoko kufuneka yomiswe. Iqondo lokushisa lokumisa liyi-80-90℃kwaye ixesha lokumisa lingaphezu kweeyure ezi-3. Izinto ezisetyenzisiweyo zinokusetyenziswa kwi-100% kwezinye iimeko. Isixa sangempela sixhomekeke kwiimfuno zomgangatho, ngokuqhelekileyo ngaphezu kwe-30%. Izinto ezisetyenzisiweyo kufuneka zigwenywe ekungcoleni, ngaphandle koko kuya kuchaphazela ukungafihli kunye neempawu zemveliso egqityiweyo.

2. Ukukhethwa komatshini wokubumba inaliti

I-PMMA ayinazo iimfuno ezikhethekileyo zoomatshini bokubumba inaliti. Ngenxa ye-viscosity ephezulu yokunyibilika kwayo, ifuna umsele onzulu kunye nomngxuma omkhulu wombhobho. Ukuba iimfuno zamandla emveliso ziphezulu, i-screw ene-aspect ratio enkulu kufuneka isetyenziswe kwi-plasticization yobushushu obuphantsi. Ukongeza, i-PMMA kufuneka igcinwe kwi-hopper eyomileyo.

3. Uyilo lokungunda kunye nesango

Ubushushu bomngundo bunokuba ngama-60℃-80℃. Ububanzi bomjelo oyintloko kufuneka buhambelane ne-taper yangaphakathi. Eyona engile ilungileyo sisi-5° ukuya 7°. Ukuba ufuna ukutofa umngundo oyi-4mm okanye ngaphezulu kweemveliso, i-engile kufuneka ibe sisi-7° kwaye ububanzi bejelo eliphambili kufuneka libe ngu-8 ukuya ku-8°. I-10mm, ubude besango bubonke akufunekanga budlule kwi-50mm. Kwiimveliso ezinobunzima bodonga obungaphantsi kwe-4mm, i-diameter ye-flow channel kufuneka ibe yi-6-8mm

Kwiimveliso ezinobunzima bodonga ngaphezu kwe-4mm, ububanzi bomgijimi kufuneka bube yi-8-12mm. Ubunzulu be-diagonal, i-fan-shaped kunye neengcango zesilayi esithe nkqo kufuneka zibe yi-0.7 ukuya kwi-0.9t (t bubunzima bodonga lwemveliso). Ububanzi besango lenaliti kufuneka libe ngu-0.8 ukuya ku-2mm; ubungakanani obuncinci kufuneka bukhethwe kwi-viscosity ephantsi.

Imingxunya eqhelekileyo ingaphakathi kwe-0.05 ubunzulu, 6 mm ububanzi, kwaye i-engile eyidrafti iphakathi kwama-30."-1° kwaye indawo yomngxuma iphakathi kwama-35"-1°30°.

4. Ubushushu obunyibilikayo

Inokulinganiswa ngendlela yokutofa emoyeni: ukusuka kwi-210℃ukuya kwi270℃, kuxhomekeke kulwazi olunikezelwe ngumthengisi.

Phuma kwisitulo esingasemva, yenza umbhobho womatshini wokubumba inaliti ushiye i-channel bushing, emva koko wenze ukubumba ngesitofu seplastiki ngesandla, okukubumba inaliti yomoya.

5. Iqondo lokushisa lokutofa

Isitofu esikhawulezayo sinokusetyenziswa, kodwa ukuphepha uxinzelelo lwangaphakathi oluphezulu, kungcono ukusebenzisa inaliti yamanqanaba amaninzi, njengokucotha-okukhawulezayo, njl njl. Xa utofa iindawo ezishinyeneyo, sebenzisa isantya esicothayo.

6. Ixesha lokuhlala

Ukuba ubushushu bungama-260°C, ixesha lokuhlala alikwazi ukudlula imizuzu eyi-10. Ukuba ubushushu bungama-270°C, ixesha lokuhlala alikwazi ukudlula imizuzu eyi-8.

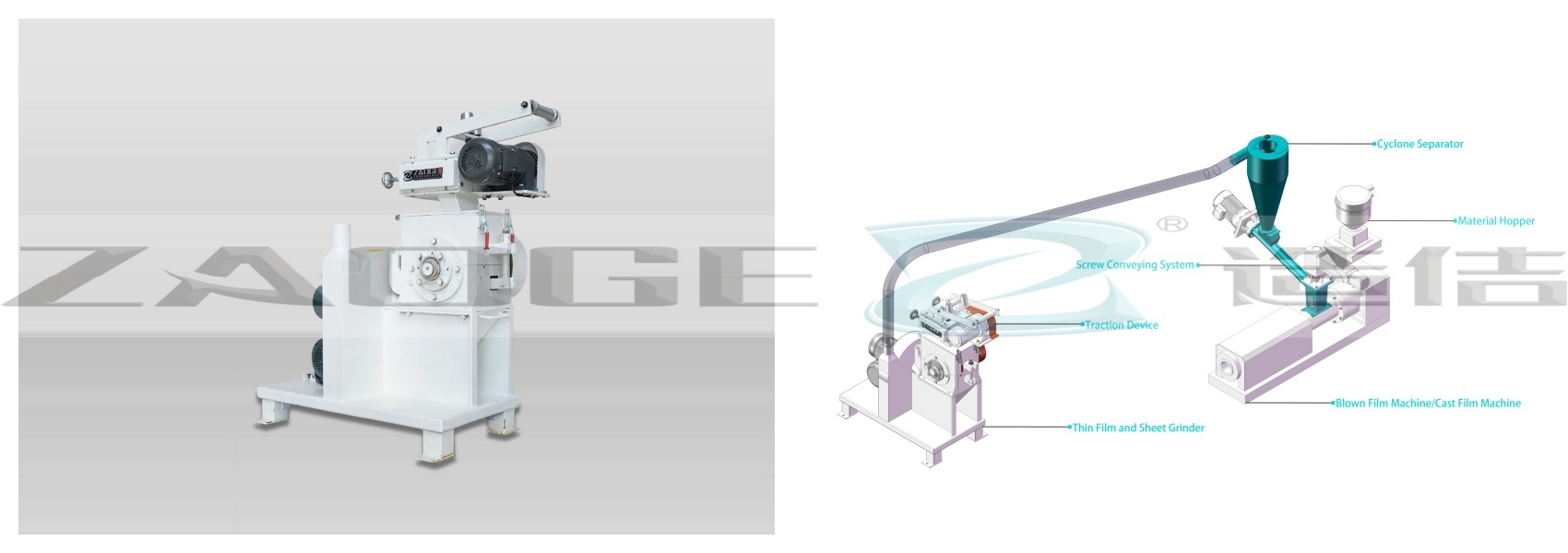

ZAOGE Film Crusherilungele ukutyumza izinto ezilahliweyo ezahlukeneyo ezithambileyo nezilukhuni ezinobunzima obuyi-0.02 ~ 5MM, njengePP/PE/PVC/PS/GPPS/PMMA films, sheets, and plates ezisetyenziswa kwizinto zokubhala, ukupakishwa, kunye namanye amashishini.

Ingasetyenziselwa ukuqokelela, ukutyumza kunye nokuhambisa izinto ezilahliweyo eziveliswe zii-extruders, i-laminators, oomatshini beshiti, kunye noomatshini beepleyiti. Umzekelo, izinto ezityumkileyo zithuthwa yifeni ehambisa ngombhobho ukuya kwisahluli senkanyamba, emva koko zityhalelwe kwi-extruder screw feed port ngesikrufu sokuxutywa ngokuzenzekelayo kunye nemathiriyeli entsha, ngaloo ndlela kuzuzwa ukhuseleko lokusingqongileyo ngoko nangoko kunye nokusetyenziswa.

Ixesha lokuposa: Jul-01-2024