1. Ukomisa inayiloni PA66

Ukomisa ngevacuum:ubushushu ℃ 95-105 ixesha 6-8 iiyure

Ukomisa umoya oshushu:ubushushu ℃ 90-100 ixesha malunga 4 iiyure.

Ubucwebe:Ngaphandle kwenayiloni ecacileyo, iinayiloni ezininzi ziyi-crystalline polymers kunye ne-crystallinity ephezulu. Amandla okuqina, ukuxhathisa ukunxiba, ukuqina, ukuthambisa kunye nezinye iipropathi zeemveliso ziphuculwe, kwaye i-coefficient yokwandisa i-thermal kunye nokufunxwa kwamanzi kudla ngokuncipha, kodwa akwenzeki ukucaca kunye nokuchasana kwempembelelo. Ubushushu bomngundo bunempembelelo enkulu kwicrystallization. Okukhona ubushushu bomngundo buphezulu, kokukhona ubukhazikhazi bekristale. Iqondo lobushushu lokungunda lisezantsi, kokukhona lisezantsi ikristale.

Ukucutheka:Ngokufanayo nezinye iiplastiki zekristale, intlaka yenayiloni inengxaki enkulu yokuncipha. Ngokuqhelekileyo, ukushwabana kwenylon kunxulumene kakhulu necrystallization. Xa imveliso inezinga eliphezulu le-crystallinity, i-shrinkage yemveliso iya kwanda. Ukunciphisa ubushushu bokubumba, ukwandisa uxinzelelo lwenaliti, kunye nokunciphisa ubushushu bezinto eziphathekayo ngexesha lenkqubo yokubumba kuya kunciphisa ukuncipha, kodwa uxinzelelo lwangaphakathi lwemveliso luya kwanda kwaye kuya kuba lula ukukhubazeka. PA66 ukucutheka yi 1.5-2%

Izixhobo zokubumba: Xa ubumba inayiloni, nikela ingqalelo ekuthinteleni "isiganeko sokuphosa somlomo", ngoko ke imilomo yokuzivalela isetyenziselwa ukusetyenzwa kwemathiriyeli yenayiloni.

2. Iimveliso kunye nokubumba

- 1. Ubukhulu bodonga lwemveliso Umlinganiselo wobude bokuhamba kwenylon uphakathi kwe-150-200. Ubukhulu bodonga lweemveliso zenayiloni abukho ngaphantsi kwe-0.8mm kwaye bukhethwa ngokubanzi phakathi kwe-1-3.2mm. Ukongezelela, i-shrinkage yemveliso ihambelana nobukhulu bodonga lwemveliso. Okukhona ukuqina kodonga, kokukhona ukuncipha.

- 2. I-Exhaust Ixabiso lokuphuphuma kwe-nylon resin li malunga ne-0.03mm, ngoko i-exhaust hole groove kufuneka ilawulwe ngaphantsi kwe-0.025.

- 3. Ubushushu bokungunda: Iindonga ezineendonga ezibhityileyo ekunzima ukuzibumba okanye ezifuna ubucwebe obuphezulu ziyafudunyezwa kwaye ziyalawuleka. Amanzi abandayo asetyenziswa ngokubanzi ukulawula ubushushu ukuba imveliso ifuna iqondo elithile lokuguquguquka.

3. Inkqubo yokubumba inayiloni

Ubushushu bomgqomo

Ngenxa yokuba inayiloni i-crystalline polymer, inendawo ebalulekileyo yokunyibilika. Iqondo lobushushu lomphanda elikhethelwe intlaka yenayiloni ngexesha lokubunjwa kwenaliti linxulumene nokusebenza kweresin ngokwayo, izixhobo, kunye nokumila kwemveliso. Inayiloni 66 yi260°C. Ngenxa yokungazinzi kwe-thermal ye-nylon, ayifanelekanga ukuhlala kwi-barrel kwiqondo lokushisa eliphezulu ixesha elide ukuphepha ukuguqulwa kombala kunye nokutyheli kwezinto. Kwangaxeshanye, ngenxa yobumanzi obuhle benayiloni, iqukuqela ngokukhawuleza emva kokuba ubushushu budlule kwindawo yayo yokunyibilika.

Uxinzelelo lwesitofu

I-viscosity ye-nayiloni enyibilikayo iphantsi kwaye i-fluidity ilungile, kodwa isantya se-condensation siyakhawuleza. Kulula ukuba neengxaki ezingonelanga kwiimveliso ezinemilo entsonkothileyo kunye neendonga ezibhityileyo, ngoko uxinzelelo oluphezulu lwenaliti lusafuneka.

Ngokuqhelekileyo, ukuba uxinzelelo luphezulu kakhulu, imveliso iya kuba neengxaki zokuphuphuma; ukuba uxinzelelo luphantsi kakhulu, imveliso iya kuba neziphene ezinjengama-ripples, ama-bubbles, amanqaku acacileyo e-sintering okanye iimveliso ezingonelanga. Uxinzelelo lwenaliti yeentlobo ezininzi zenayiloni alugqithi kwi-120MPA. Ngokubanzi, ikhethwa phakathi koluhlu lwe-60-100MPA ukuhlangabezana neemfuno zeemveliso ezininzi. Ngethuba nje imveliso ingenazo iziphene ezinjengamaqamu kunye nezibonda, ngokuqhelekileyo akunqweneleki ukusebenzisa uxinzelelo oluphezulu lokubamba ukuphepha ukwandisa uxinzelelo lwangaphakathi kwimveliso. Isantya se-injection Kwi-nylon, isantya se-injection sikhawuleza, esinokuthi sithintele i-ripples kunye nokungonelanga kokugcwalisa isikhunta okubangelwa isantya sokupholisa ngokukhawuleza. Isantya senaliti esikhawulezayo asinayo impembelelo ebalulekileyo ekusebenzeni kwemveliso.

Ubushushu bomngundo

Ubushushu bomngundo bunempembelelo ethile kwikristale kunye nokuncipha kokubumba. Ubushushu obuphezulu bokubumba bunobukristale obuphezulu, ukwanda kokunganyangeki, ukuqina, imodyuli e-elastic, ukunciphisa ukufunxa kwamanzi, kunye nokunyuka kokubunjwa kwemveliso; iqondo lobushushu elisezantsi lokungunda linobukristale obuphantsi, ukuqina okuhle, kunye nobude obuphezulu.

Iindibano zocweyo zokubumba izitofu zivelisa izihluzi kunye neembaleki yonke imihla, ke singenza njani ngokulula nangempumelelo ukuseyisa kwakhona izitshizi kunye neembaleki eziveliswe ngoomatshini bokubumba inaliti?

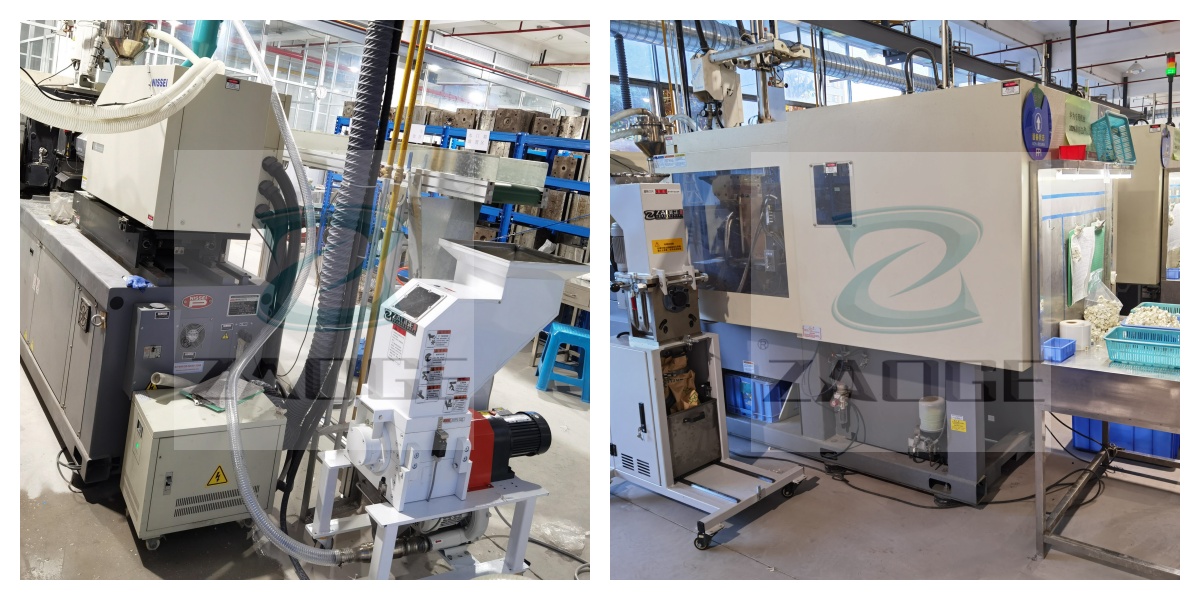

YiyekeI-ZAOGE ukhuseleko lokusingqongileyo kunye nesixhobo esixhasayo sokugcina izinto (iplastiki yokutyumza)koomatshini bokubumba inaliti.

Yinkqubo yexesha lokwenyani eshushu egayiweyo nesetyenzisiweyo eseyilwe ngokukodwa ukutyumza i-sprues evuthulukileyo yobushushu kunye neembaleki.

Amasuntswana atyumkileyo acocekileyo nawomileyo abuyiselwa ngoko nangoko kumgca wemveliso ukuvelisa ngoko nangoko iimveliso zezahlulo ezibunjiweyo ze-Injection.

Amasuntswana acoliweyo acocekileyo nawomileyo aguqulwa abe yimathiriyeli ekrwada ekumgangatho ophezulu ukuze isetyenziswe endaweni yokuthotywa.

Igcina imathiriyeli ekrwada kunye nemali kwaye ivumela ulawulo olungcono lwamaxabiso.

isikrini esicothayo sejenali yesantya

Ixesha lokuposa: Jul-24-2024