(1) Ukukhethwa kwezixhobo ezingafanelekanga.Xa ukhetha izixhobo, umthamo omkhulu wenaliti yomatshini wokubumba inaliti kufuneka ube mkhulu kunobunzima obupheleleyo benxalenye yeplastiki kunye nombhobho, kwaye ubunzima benaliti bubonke abunakudlula i-85% yomthamo weplastikhi yomatshini wokubumba.

(2) Ukutya okungonelanga.Indlela eqhelekileyo esetyenziswayo yokulawula isondlo yindlela yokutya yevolumu esisigxina. Umthamo we-roller feed kunye nobukhulu be-particle ye-raw material ifanayo, kwaye ingaba kukho "ibhulorho" into ephantsi kwe-port feed. Ukuba iqondo lobushushu kwizibuko lokutya liphezulu kakhulu, oko kuya kubangela ukuhla kwempahla engalunganga. Ngokubhekiselele koku, izibuko lokutya kufuneka livulwe kwaye lipholiswe.

(3) Ubumanzi bezinto eziphathekayo.Xa i-fluidity ekrwada ihlwempuzekile, iiparamitha zesakhiwo somngundo sesona sizathu sokungoneli kwesitofu. Ke ngoko, iziphene zokuma kwenkqubo yokuphosa yokubumba kufuneka ziphuculwe, njengokuseta ngokufanelekileyo indawo yembaleki, ukwandisa isango, imbaleki kunye nobukhulu bezibuko lokutofa, kunye nokusetyenziswa kombhobho omkhulu. Ngexesha elifanayo, inani elifanelekileyo lezongezo lingongezwa kwifomula yezinto eziluhlaza ukuphucula iimpawu zokuhamba kwe-resin. Ukongeza, kuyafuneka ukuba kujongwe ukuba ngaba izinto ezihlaziyiweyo kwizinto eziluhlaza zigqithise kwaye zinciphisa ngokufanelekileyo isixa sazo.

(4) I-lubricant egqithisileyo.Ukuba isixa se-lubricant kwifomula yezinto ekrwada sininzi kakhulu, kwaye umsantsa wokunxiba phakathi kweringi yokujonga isijivu sokutofa kunye nomphanda mkhulu, izinto ezinyibilikisiweyo ziya kubuyela umva kanobom emgqomeni, kubangele ukondla okungonelanga kwaye kubangele isitofu esingaphantsi. Kule nkalo, isixa se-lubricant kufuneka sincitshiswe, i-gap phakathi kwe-barrel kunye ne-injection screw kunye ne-ring ring kufuneka ilungiswe, kwaye izixhobo kufuneka zilungiswe.

(5) Izinto ezingcolileyo ezibandayo zivala umjelo wezinto eziphathekayo.Xa ukungcola kwimathiriyeli etyhidiweyo kuthintela umlomo okanye imathiriyeli ebandayo ivala isango kunye nembaleki, umlomo kufuneka ususwe kwaye ucocwe okanye umngxuma wezinto ezibandayo kunye necandelo lembaleki lokungunda kufuneka landiswe.

(6) Uyilo olungenangqiqo lwenkqubo yokugalela.Xa isikhunta sinemingxuma emininzi, iziphene zokubonakala kweengxenye zeplastiki zihlala zibangelwa kuyilo olungenangqiqo lwesango kunye nebhalansi yomgijimi. Xa uyila inkqubo yokuthulula, nikela ingqalelo kwibhalansi yesango. Ubunzima beengxenye zeplastiki kwisithuba ngasinye kufuneka bulingane nobukhulu besango ukwenzela ukuba umgodi ngamnye unokuzaliswa ngexesha elinye. Isikhundla sesango kufuneka sikhethwe eludongeni olungqingqwa. Isicwangciso soyilo lweplanner yolungelelwaniso lwebala elicandiweyo sinokumkelwa. Ukuba isango okanye umgijimi lincinci, lincinci, kwaye lide, uxinzelelo lwezinto ezityhidiweyo ziya kulahleka kakhulu kunye nenkqubo yokuhamba, ukuhamba kuya kuvinjelwa, kwaye ukuzaliswa kakubi kunokwenzeka. Kule nkalo, icandelo lokuwela umnqamlezo kunye nommandla wesango kufuneka landiswe, kwaye indlela yokutya yamanqaku amaninzi ingasetyenziselwa ukuba kuyimfuneko.

(7) Umbhobho ongekho mgangathweni.Xa isixa esikhulu segesi esisele kwisikhunta ngenxa yokukhutshwa okungahambi kakuhle kucinezelwa ngokuhamba kwezinto, ukuvelisa uxinzelelo oluphezulu kunoxinzelelo lwe-injection, kuya kuthintela izinto ezityhidiweyo ukuba zizalise i-cavity kwaye zibangele ngaphantsi kwe-injection. Kule nkalo, kufuneka kuhlolwe ukuba ngaba umgodi wezinto ezibandayo ubekiwe okanye ukuba indawo yayo ichanekile. Kwimibumbo enemingxuma enzulu, i-grooves yokukhupha okanye imingxuma yokukhupha kufuneka yongezwe kwindawo engaphantsi kwe-injection; kwi-mold surface, i-groove yokukhupha i-groove enobunzulu be-0.02 ~ 0.04 mm kunye nobubanzi be-5 ~ 10 mm ingavulwa, kwaye umngxuma wokukhupha kufuneka ubekwe kwindawo yokugqibela yokuzaliswa kwendawo.

Xa usebenzisa izinto eziluhlaza ezinobumanzi obugqithisileyo kunye nomxholo oguquguqukayo, isixa esikhulu segesi siya kuveliswa, okukhokelela ekukhupheni okungalunganga kokungunda. Ngeli xesha, izinto eziluhlaza kufuneka zomiswe kwaye i-volatiles kufuneka isuswe.

Ukongezelela, ngokubhekiselele kwinkqubo yokusebenza kwenkqubo yokubumba, ukukhupha okungahambi kakuhle kunokuphuculwa ngokunyusa ubushushu bokubumba, ukunciphisa isantya senaliti, ukunciphisa ukuchasana kokuhamba kwenkqubo yokuthululela, ukunciphisa amandla okubamba, kunye nokwandisa isithuba sokubumba.

(8) Iqondo lobushushu lokungunda liphantsi kakhulu.Emva kokuba izinto ezityhidiweyo zingene kwi-mold mold cavity ephantsi, ayiyi kukwazi ukuzalisa zonke iikona zomgobo ngenxa yokupholisa ngokukhawuleza. Ngoko ke, isikhunta kufuneka sifudunyezwe kwiqondo lokushisa elifunwa yinkqubo ngaphambi kokuqala umatshini. Xa umatshini usandula ukuqaliswa, ubungakanani bamanzi okupholisa adlula kwi-mold kufuneka ilawulwe ngokufanelekileyo. Ukuba iqondo lobushushu lokungunda alinakunyuka, uyilo lwesixokelelwano sokupholisa sokungunda kufuneka lujongwe ukuba lufanelekile na.

(9) Iqondo lobushushu lokunyibilika liphantsi kakhulu.Ngokuqhelekileyo, ngaphakathi koluhlu olufanelekileyo lokubumba, ukushisa kwezinto eziphathekayo kunye nobude bokuzaliswa busondele kubudlelwane obuhle obulinganayo. Ukusebenza kokuhamba kweqondo lokushisa eliphantsi liyancipha, elinciphisa ubude bokuzalisa. Xa ubushushu bezinto eziphathekayo bungaphantsi kobushushu obufunwa yinkqubo, khangela ukuba i-barrel feeder ilungile kwaye uzame ukunyusa ubushushu bombhobho.

Xa umatshini uqalwa nje, ubushushu bomgqomo buhlala buphantsi kunobushushu obuboniswa sisixhobo sokufudumeza umphanda. Kufuneka kuqatshelwe ukuba emva kokuba umgqomo ufudunyezwe kwiqondo lokushisa lesixhobo, kusafuneka upholiswe ixesha elithile ngaphambi kokuba umatshini uqaliswe.

Ukuba inaliti yobushushu obuphantsi buyimfuneko ukuthintela ukubola kwezinto ezinyibilikisiweyo, ixesha lokujikwa kwenaliti linokwandiswa ngokufanelekileyo ukuze liloyise ngaphantsi kwe-injection. Kumatshini wokubumba inaliti ye-screw, ubushushu becandelo langaphambili lombhobho linokwandiswa ngokufanelekileyo.

(10) Ubushushu bombhobho buphantsi kakhulu.Ngethuba lenkqubo yokutofa, i-nozzle idibene ne-mold. Njengoko iqondo lobushushu lokungunda lingaphantsi kobushushu bombhobho kwaye umahluko wobushushu mkhulu, ukudibana rhoqo phakathi kwezi zibini kuya kubangela ukuba ubushushu bombhobho buhle, nto leyo ekhokelela ekubeni imathiriyeli enyibilikisiweyo ibe ngumkhenkce emlonyeni.

Ukuba akukho mgodi wezinto ezibandayo kwi-mold structure, izinto ezibandayo ziya kuqina ngokukhawuleza emva kokungena kwi-cavity, ukwenzela ukuba i-hot melt ngasemva ayikwazi ukuzalisa i-cavity. Ngoko ke, i-nozzle kufuneka ihlulwe kwi-mold xa uvula i-mold ukunciphisa impembelelo yeqondo lokushisa kwi-nozzle kunye nokugcina ubushushu kwi-nozzle ngaphakathi koluhlu olufunwa yinkqubo.

Ukuba iqondo lobushushu lombhobho liphantsi kakhulu kwaye alinakunyuswa, jonga ukuba isifudumezi sombhobho sonakaliswe kwaye uzame ukunyusa ubushushu bombhobho. Ngaphandle koko, ukulahlekelwa kwengcinezelo yezinto ezihambayo kukhulu kakhulu kwaye kuya kubangela ukuba ngaphantsi kwe-injection.

(11) Uxinzelelo lwenaliti olunganeleyo okanye ukubamba uxinzelelo.Uxinzelelo lwenaliti lusondele kubudlelwane obuhle obulinganayo kunye nobude bokuzalisa. Ukuba uxinzelelo lwenaliti luncinci kakhulu, ubude bokuzaliswa bufutshane kwaye i-cavity ayigcwaliswa ngokupheleleyo. Kule meko, uxinzelelo lwenaliti lunokunyuswa ngokunciphisa isantya sokujova phambili kunye nokwandisa ixesha lokutofa ngokufanelekileyo.

Ukuba uxinzelelo lwenaliti alunakunyuswa ngakumbi, lunokulungiswa ngokunyusa ubushushu bezinto eziphathekayo, ukunciphisa i-viscosity yokunyibilika, kunye nokuphucula ukusebenza kokunyibilika. Kuyafaneleka ukuba uqaphele ukuba ukuba ubushushu bezinto eziphathekayo buphezulu kakhulu, izinto ezityhidiweyo ziya kuchithwa nge-thermal, ezichaphazela ukusebenza kwenxalenye yeplastiki.

Ukongezelela, ukuba ixesha lokubamba lifutshane kakhulu, liya kukhokelela ekuzalisweni okunganeleyo. Ngoko ke, ixesha lokubamba kufuneka lilawulwe ngaphakathi koluhlu olufanelekileyo, kodwa kufuneka kuqatshelwe ukuba ixesha elide lokubamba liza kubangela nezinye iimpazamo. Ngexesha lokubumba, kufuneka lilungiswe ngokwemeko ethile yenxalenye yeplastiki.

(12) Isantya sokutofa sicotha kakhulu.Isantya senaliti sihambelana ngqo nesantya sokuzalisa. Ukuba isantya sokutofa sicotha kakhulu, izinto ezinyibilikisiweyo zigcwalisa ukungunda ngokucothayo, kwaye isantya esisezantsi esigelezayo sesixhobo esityhidiweyo kulula ukupholisa, nto leyo enciphisa ngakumbi ukusebenza kwayo kwaye ibangele isitofu esingaphantsi.

Kulo mba, isantya sokutofa kufuneka sandiswe ngokufanelekileyo. Nangona kunjalo, kufuneka kuqatshelwe ukuba ukuba isantya senaliti sikhawuleza kakhulu, kulula ukubangela ezinye iimpazamo zokubumba.

(13) Uyilo lwesakhiwo senxalenye yeplastiki alunangqiqo.Xa ubukhulu becala leplastiki bungalingani nobude, imilo inzima kakhulu kwaye indawo yokubumba inkulu, izinto ezityhidiweyo zivaliwe ngokulula ekungeneni kwendawo encinci yeplastiki, okwenza kube nzima ukuzalisa umgodi. Ngoko ke, xa uyila isakhiwo semilo yecandelo leplastiki, kufuneka kuqatshelwe ukuba ubukhulu becala leplastiki lihambelana nomda wokuhamba kobude bezinto ezityhidiweyo ngexesha lokuzaliswa kwesikhunta.

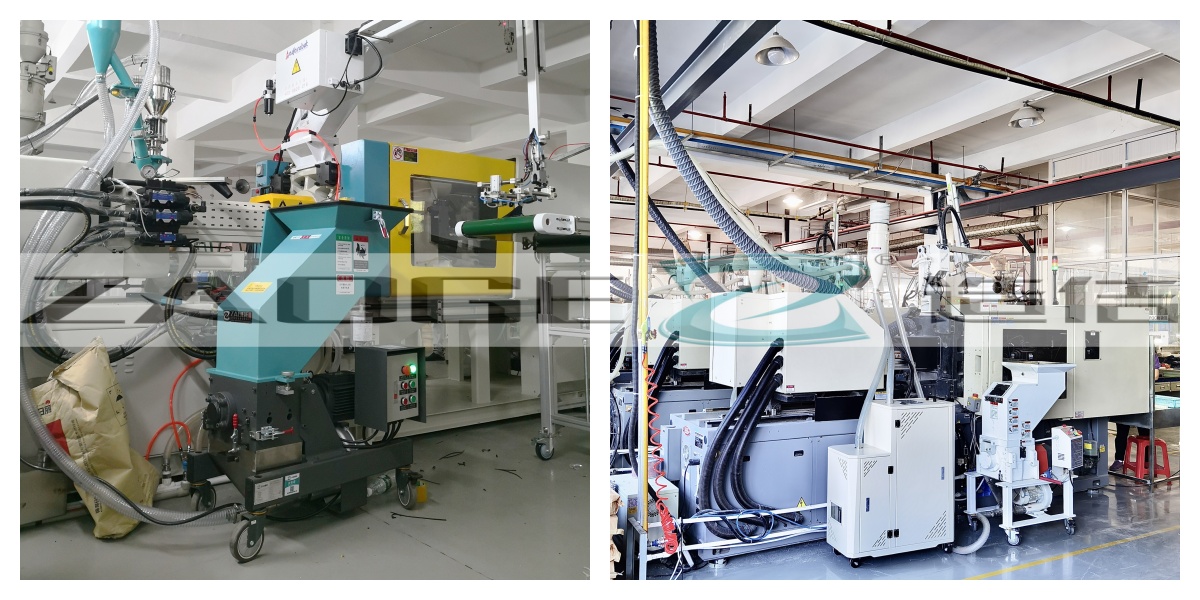

Ke singenza njani ngokulula nangokusebenzayo siphinde sisebenzise imathiriyeli yembaleki eveliswe ngumatshini wokubumba inaliti?ZAOGE'sipatented inline ukutyunyuzwa okushushu ngoko nangoko kunye nesisombululo somgangatho ophezulu wokurisayikilisha kwangoko. To lawula ngcono umgangatho wemvelisokwayeixabiso. Ezoizinto ezityumkileyo zifana, zicocekile, azinathuli, azingcolisi, umgangatho ophezulu, zixutywe nezinto ezikrwada ukuvelisa iimveliso ezikumgangatho ophezulu.

Ixesha lokuposa: Jul-10-2024